Condition:

New

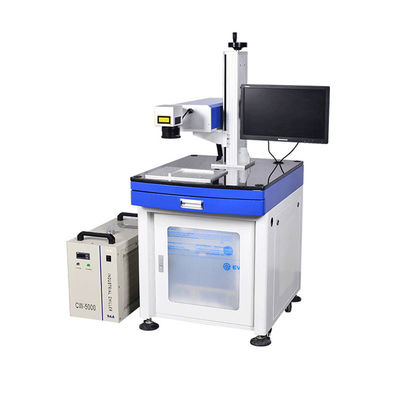

Power:

200W

Applicable Material:

Stainless Steel, Carbon Steel, Aluminum, Metal

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty Of Core Components:

2 Years

Core Components:

Laser

Laser Type:

Fiber Laser

Dimension(L*W*H):

1100mmx700mmx1150mm

Year:

2021

Laser Source Brand:

Optional Brand

Laser Head Brand:

Optional Brand

Guiderail Brand:

Optional Brand

Control System Brand:

Optional Brand

Weight (KG):

270 KG

Key Selling Points:

Easy To Operate

Warranty:

1 Year

Applicable Industries:

Printing Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Construction Works , Machinery Repair Shops, Energy & Mining, Building Material Shops, Other

Local Service Location:

None

Showroom Location:

None

Product Name:

200W Pulse Laser Cleaning Machine

Fiber Length:

5 Meters (10 Meters Can Be Customized)

Move Method:

Hand Held

Scan Width:

10-80mm

Washing Head Weight:

2.5Kg

Cleaning Efficiency:

5m2/h

Focal Length:

210/160mm Replaceable

Cooling Method:

Water Cooling

Working Temperature:

0℃~40℃

Working Environment Humidity:

≤80%

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!